China Wholesale Induction Brazing Coils Manufacturers - Induction bending machine – Duolin

China Wholesale Induction Brazing Coils Manufacturers - Induction bending machine – Duolin Detail:

Products Description

Induction pipe bending process uses induction coil heats a narrow, circumferential section of the pipe to a temperature 850-1100 degrees Celsius (dependant on the material to be formed), the pipe is moved slowly through the induction coil whilst the bending force is applied by a fixed radius arm arrangement.

Induction hot bender is known for its high quality, accuracy bending and cost savings. Induction bends provide bending of large sections – particularly pipe and other hollow sections, widely used for Roadway signage, Construction (structural shapes), Pipeline for oil & gas (on and offshore), Hot water pipes, Pipeline for chemical raw material, Pipeline for electric wires.

Induction Bend is perfect for these industries:

●Highway billboards

●Structure construction

●Oi and gas (onshore and offshore) pipelines

●Chemica and petrochemica pipelines

●Shipbuilding

Bending type: Pipe, Square tube, Rectangle tube, Beam

Material:

● Seamless tube: 20G、 A106B、A106C etc.

● Longitudinally welded pipes:235B、345B、X42、X52、X60、X70、X80 etc.

Alloy steel:335P12、P22、P91、12Cr1MoVG、WB36 etc.

Feature

1: Keep a constant heating temperature when bending,Ensure the physical characteristics of bends or elbow.

2: The latest technology IGBT inverter technology,series resonance,more energy saving than Diode rectification,and don’t need capacitor cabinet

3: Power factor is not less than 0.95

4: Phase lock technology and automatic frequency tracking make the machine work more efficiently.

5: Precisely heating and bending,better quality bends or elbow,more cost saving

6: Can bent in different ways,square tube,rectangular tube and angle steel can be bent

7: Low installation and operation cost

8: Not require sand filling and internal mandrels

9: Superior quality at ovality and wall thinning

10:PLC control to set and store each pipe bending process parameter

| IGBT Induction Bending Machine |

Capacity |

| Induction Bending Machine 168 |

168 x 13 |

| Induction Bending Machine 325 |

325 x25 |

| Induction Bending Machine 426 |

426 x30 |

| Induction Bending Machine 530 |

530 x 30 |

| Induction Bending Machine 630 |

630 x 30 |

| Induction Bending Machine 720 |

720 x 35 |

| Induction Bending Machine 810 |

813 x 35 |

What we need to know before offer pipe hot bender solution?

1: The pipe material length wall thickness and OD

2: Bending radius and angle

3: For elbow or hot bender

4: Bending production

5: The usage of pipe,for gas oil or other industry

6: Require for ovality and wall thinning

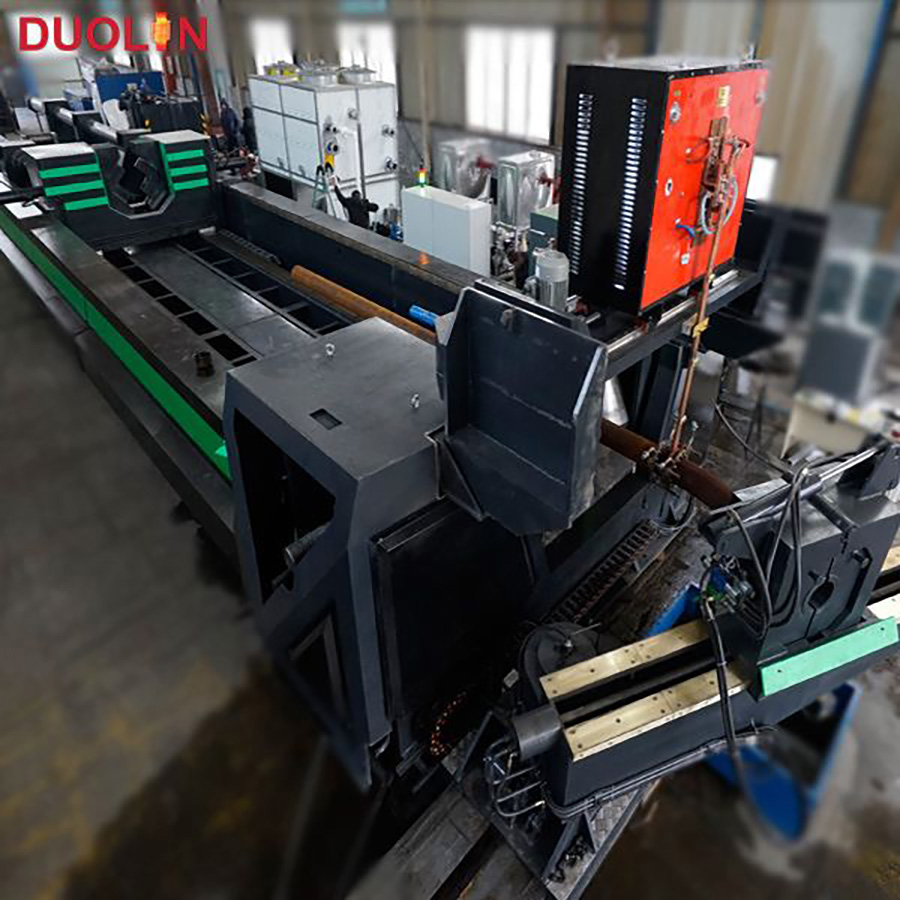

Product detail pictures:

Related Product Guide:

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for China Wholesale Induction Brazing Coils Manufacturers - Induction bending machine – Duolin , The product will supply to all over the world, such as: Luxembourg, moldova, Chile, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.