China Wholesale Induction Forge Quotes - High Quality China Monthly Deals High Frequency 15kw Metal Welding Forging Melting Induction Heating Machine – Duolin

China Wholesale Induction Forge Quotes - High Quality China Monthly Deals High Frequency 15kw Metal Welding Forging Melting Induction Heating Machine – Duolin Detail:

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value “unification, dedication, tolerance” for High Quality China Monthly Deals High Frequency 15kw Metal Welding Forging Melting Induction Heating Machine, With a wide range, top quality, sensible charges and stylish designs,Our items are widely recognized and dependable by users and can fulfill continuously changing economic and social needs.

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value “unification, dedication, tolerance” for China Induction Heater, induction heating machine, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will likely be more conveniently to service our customers.

Products Description

| Certification | CE ISO9001 2105 |

| Brand | Duolin |

| Warranty | 1 Year |

| Production capacity | 10 set one month |

| HS Code | 8514400090 |

1:100-160 KW Induction Heating Equipment adopts the IGBT inverter circuit in series connection, which has high heating efficiency

2. High power, fast heating speed, high efficiency and easy operation.

3. The comprehensive full load design is available for 24-hour continuous operation.

4: 160KW IGBT Solid state induction converter, the cabinet is well sealed, no failure and IGBT never burst.

5: Application: Hot forging, Shrink fitting, smelting, surface quench, welding, annealing

6:High conversion efficiency more than 97.5%:IGBT(Insulated Gate Bipolar Transistor)inversion technology

7:Energy saving up to 15%-30% compared with SCR technology induction machine:LC series resonance circuit and voltage feedback design, low energy comsumption

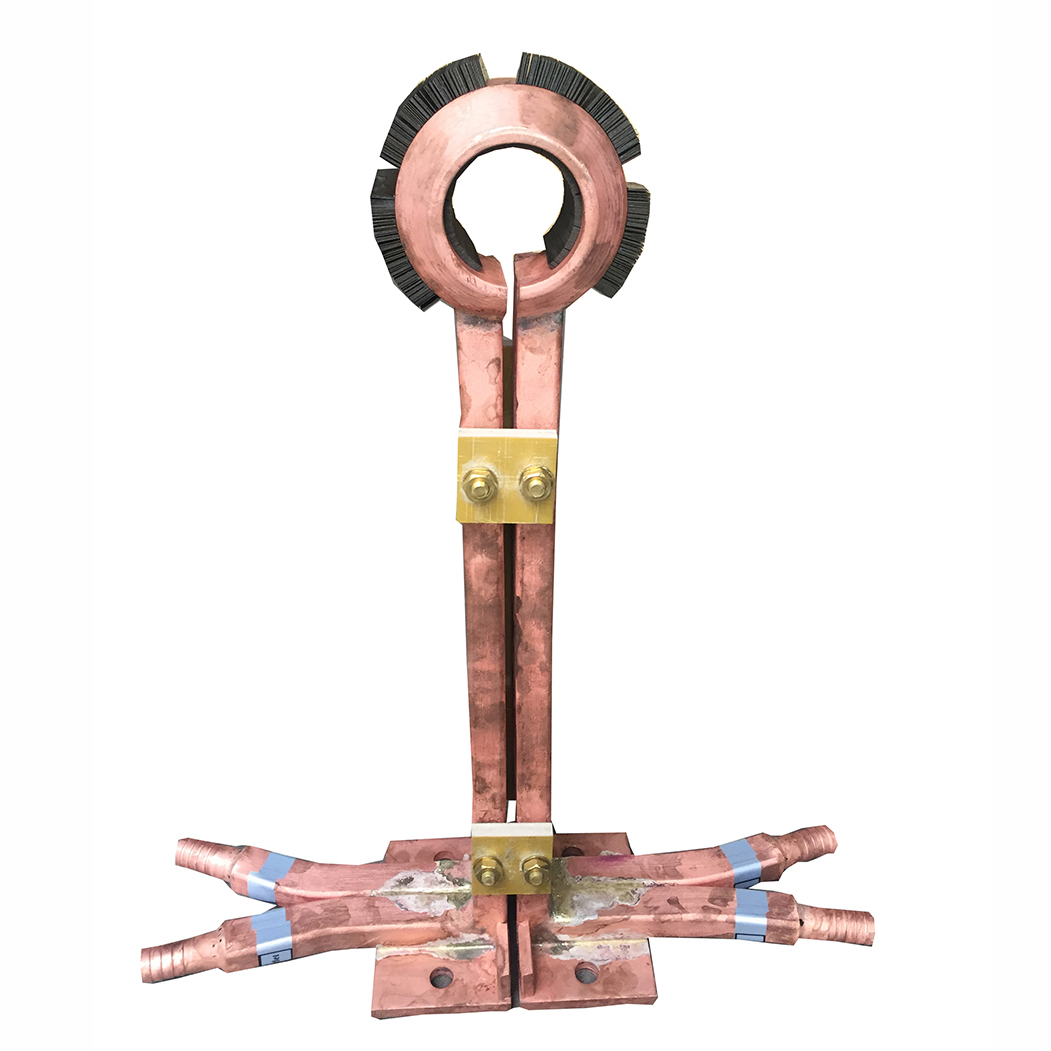

8:Cooper &stainless steel fasteners and radiator,better cooling and anti-electrolysis

Application

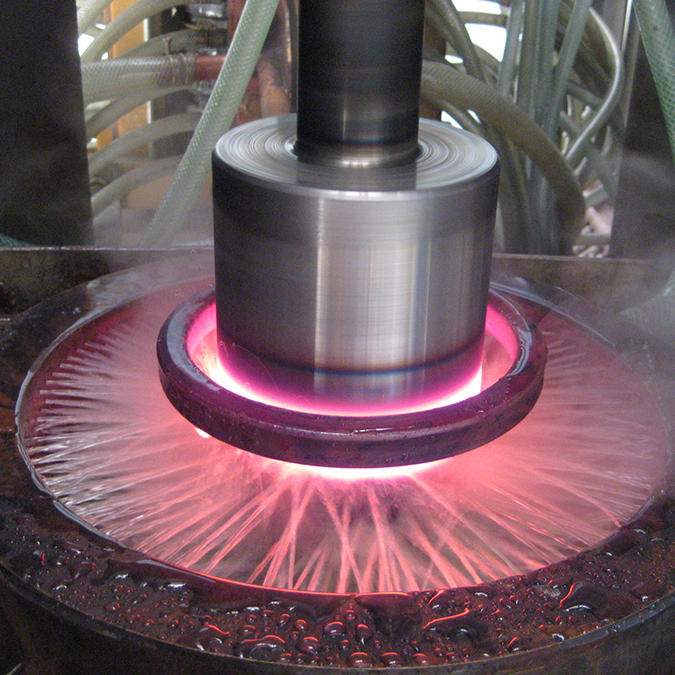

1.Preheating (billet hot forging, shrink fitting)

Billet Hot forging aims to heat the work pieces to certain temperature (different materials require different temperatures) into other shapes through forging press with the help of hot stamp or press machine, it can be full or end or head heating of bar,usually use for fastener bolts and nut and other metal related manufacture industry

2.Shrink fitting:Shrink fitting is a heating process to heat metal material creates an interference fit. The increase in hole size allows the insertion or removal of a mating components after heating and cooling.Thank to fast heating speed of induction,temperature can be controlled exactly,prevents distortion and needed metallurgical changes,the thermal expansion creates a joint,gear to shaft,flanges to hubs and bearing insertion are common for shrink fit.

3. Heat Treatment (surface scanner )

Heat treatment for various hardware or tools, such as plier, wrench, hammer, ax, screwing tools and shear (orchard shear).

Hardening for auto part and motorcycle fittings, such as crankshaft, connecting rod, piston pin, chain wheel, pump fitting ,valve, axle shaft, small shaft or steel bar and kinds of gear

Quench for machine tools, such as lathe deck or guide rail.

Induction hardening for hardware molds, such as small-size mold, mold accessory and inner hole of mold

Long bar or thread bar induction hardening and tempering, fully automatic production line

4. Brazing

Induction heating of brazing for kinds of hardware cutting tools, such as diamond tool, saw blade, drilling tool, hard alloy steel cutter, milling cutter, reamer, planning tool and solid center bit and rotor induction brazing

The brazing media are different when materials are not same,Silver is the most common,the soldering part are hardware toilet and kitchen products, refrigerating copper fitting, lamp decoration fitting, precision mold fitting, hardware handle, eggbeater, alloy steel and steel, steel and copper as well as copper and copper.

It is also applicable to plain braze welding of other metals.Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value “unification, dedication, tolerance” for High Quality China Monthly Deals High Frequency 15kw Metal Welding Forging Melting Induction Heating Machine, With a wide range, top quality, sensible charges and stylish designs,Our items are widely recognized and dependable by users and can fulfill continuously changing economic and social needs.

High Quality China Induction Heater, Induction Heating Machine, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will likely be more conveniently to service our customers.

Product detail pictures:

Related Product Guide:

We insist about the theory of growth of 'High excellent, Performance, Sincerity and Down-to-earth working approach' to offer you with great company of processing for China Wholesale Induction Forge Quotes - High Quality China Monthly Deals High Frequency 15kw Metal Welding Forging Melting Induction Heating Machine – Duolin , The product will supply to all over the world, such as: Norway, Serbia, Belgium, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.