China Wholesale Induction System Pricelist - Top Grade China DSP-160kw IGBT Digital Medium Frequency Induction Heating Equipment for Shrink Fit – Duolin

China Wholesale Induction System Pricelist - Top Grade China DSP-160kw IGBT Digital Medium Frequency Induction Heating Equipment for Shrink Fit – Duolin Detail:

We will make just about every hard work to be excellent and ideal, and accelerate our methods for standing during the rank of intercontinental top-grade and high-tech enterprises for Top Grade China DSP-160kw IGBT Digital Medium Frequency Induction Heating Equipment for Shrink Fit, Striving hard to attain continual accomplishment according to good quality, trustworthiness, integrity, and complete understanding of sector dynamics.

We will make just about every hard work to be excellent and ideal, and accelerate our methods for standing during the rank of intercontinental top-grade and high-tech enterprises for China Induction Heating Equipment, induction heating machine, Our team knows well the market demands in different countries, and is capable of supplying suitable quality goods at the best prices to different markets. Our company has already set up a expert, creative and responsible team to develop clients with the multi-win principle.

Products Description

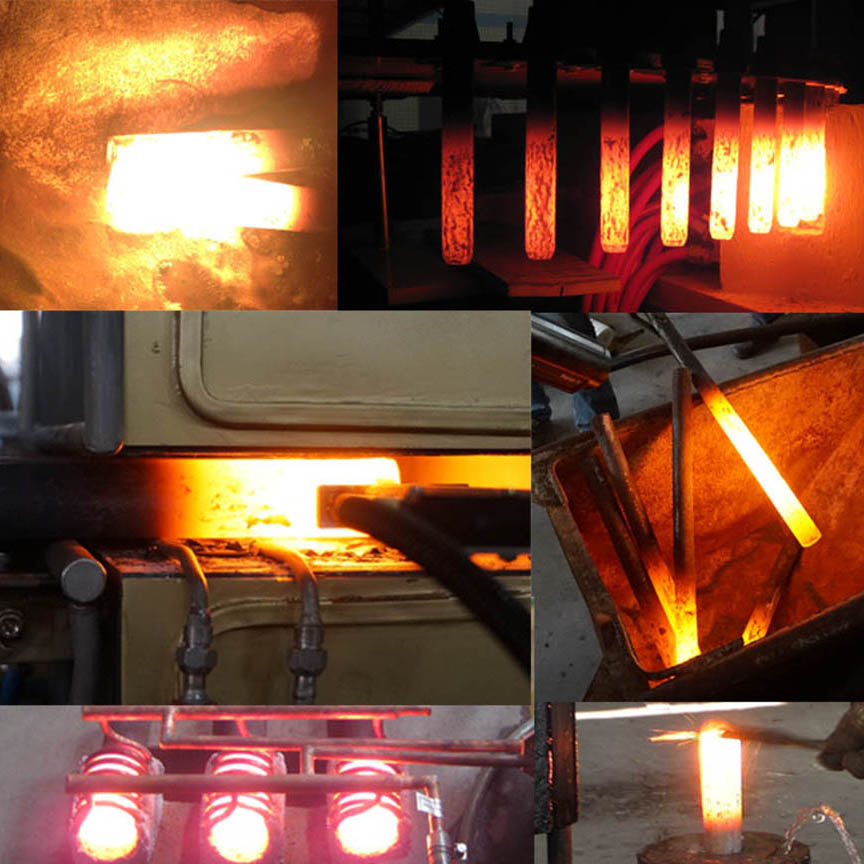

Induction forging refers to use an induction heater to pre-heat metals before forging and forming. Typically metals are heated to between 1,100 and 1,200 °C to increase their malleability and aid flow in the forging die.

Induction produces less oxidation, easy to control heating temperature and time, heat rapidly, ensure good quality of forging work piece, protect tool of forging machine.

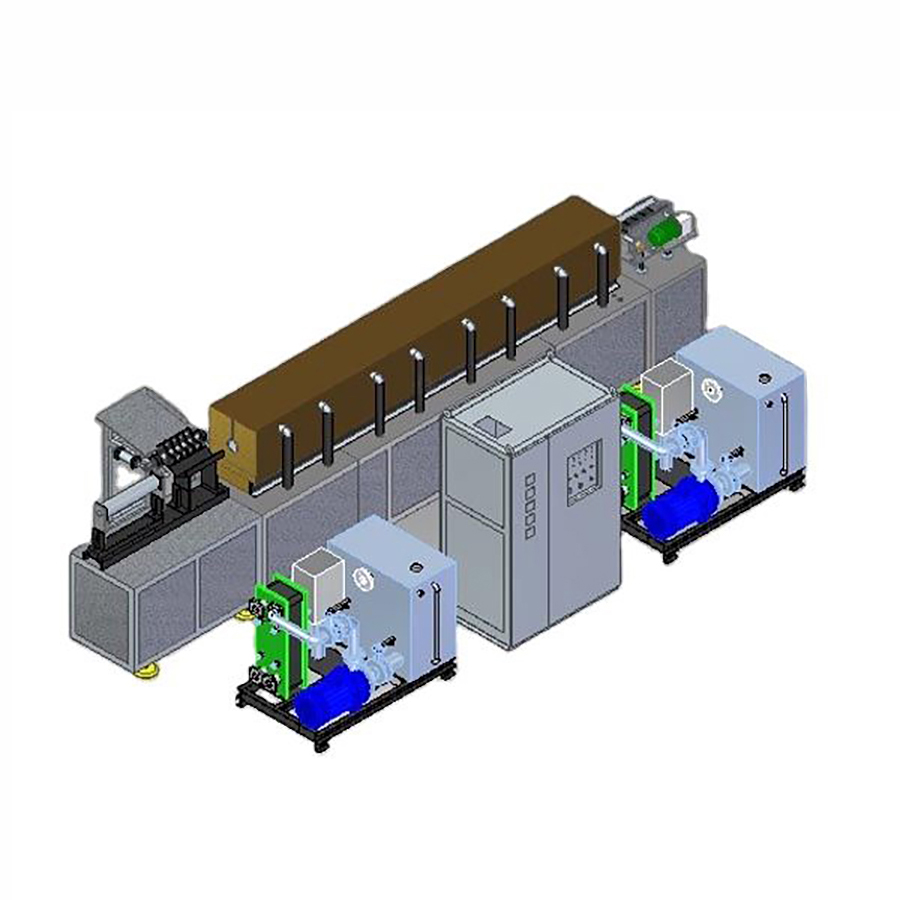

Induction billet heating line for total heating

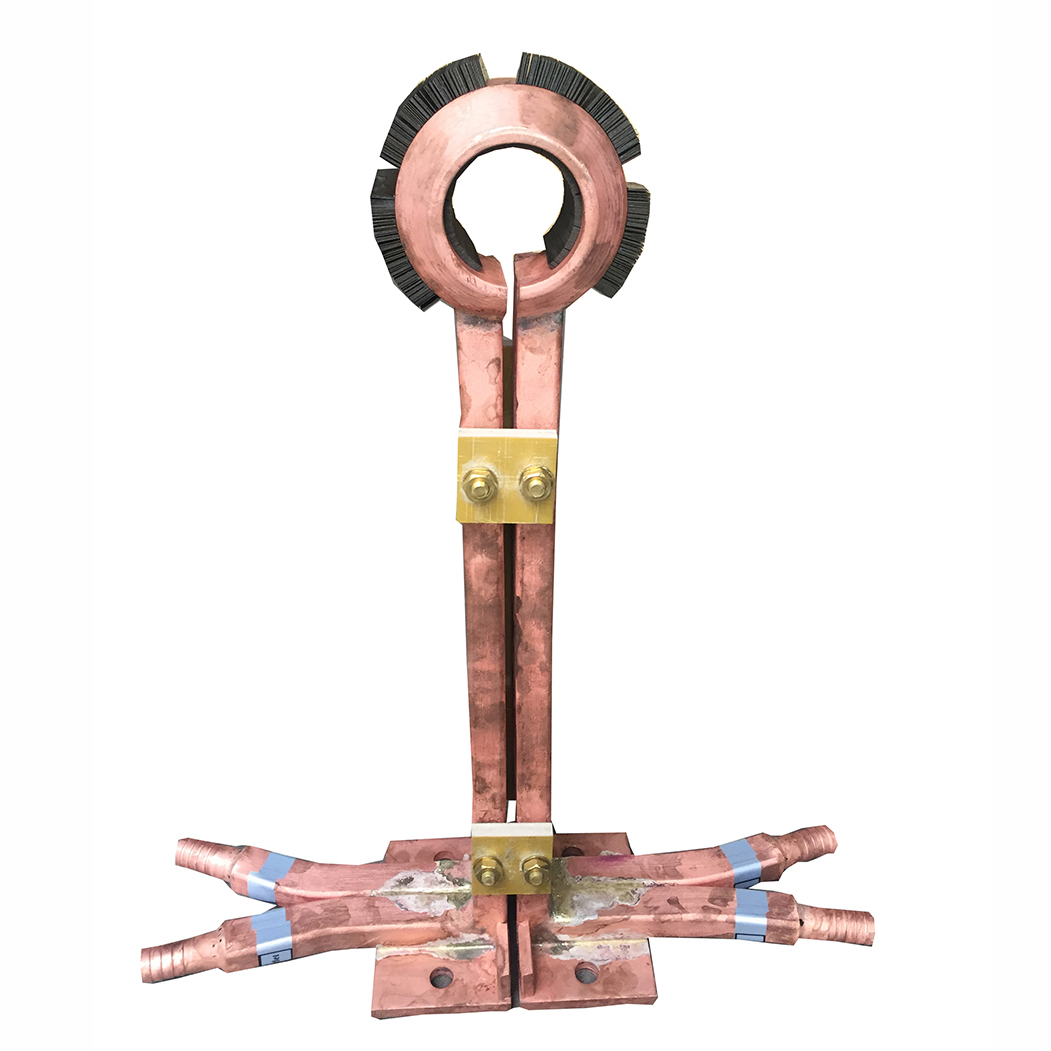

Induction heating equipment with slot inductor for partial heating

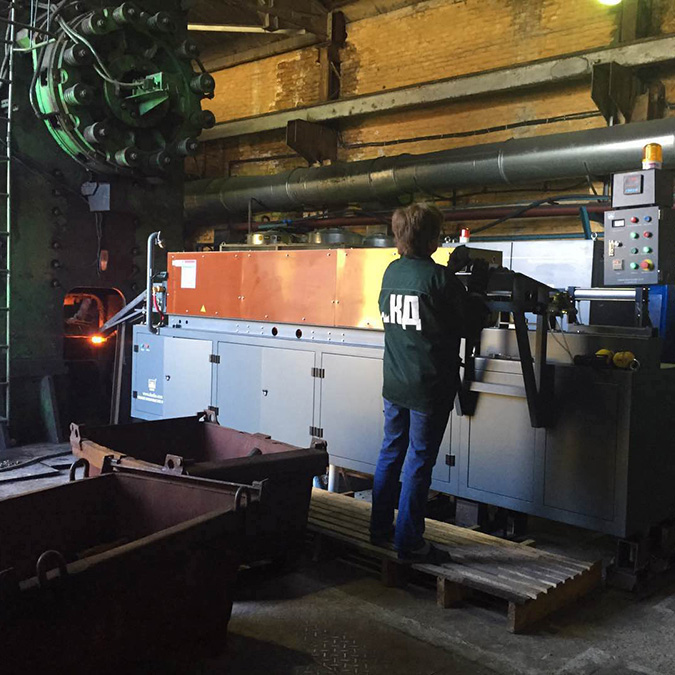

Integrated induction heat line: induction power supply built in with inductor, less space requirement, PLC control.

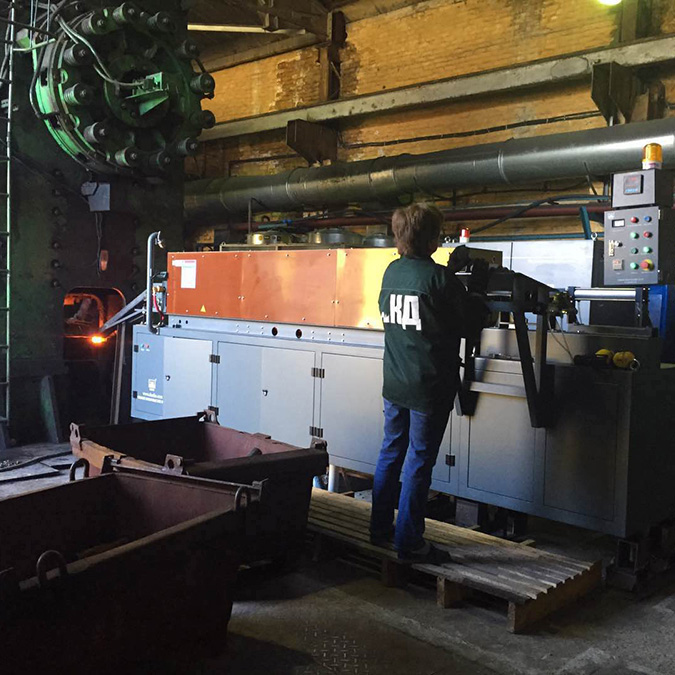

Induction heating technology is increasingly being used for industrial forging applications because it offers an unbeatable combination of speed, consistency, control and efficiency.

DUOLIN offers induction billet heater used for heating a wide range of bar and billet diameters.induction power supply is the latest generation; help you benefit from modern forging industry.

• No combustible gases

• Heating rapidly reduce oxide skin on billet

• Improve the working environment

• Uniform heating temperature increases die life

• Continuously working, 24 hours non-stop

• Be Started up 100% at any load

• Less interference to others equipment in workshop (Proved by CE)

• IGBT inversion technology & LC series circuit design achieve energy saving up to 15%-30% compared with SCR technology

• Easy to operate and maintain

• Offer PLC to complete fully automatic production line and high heating output

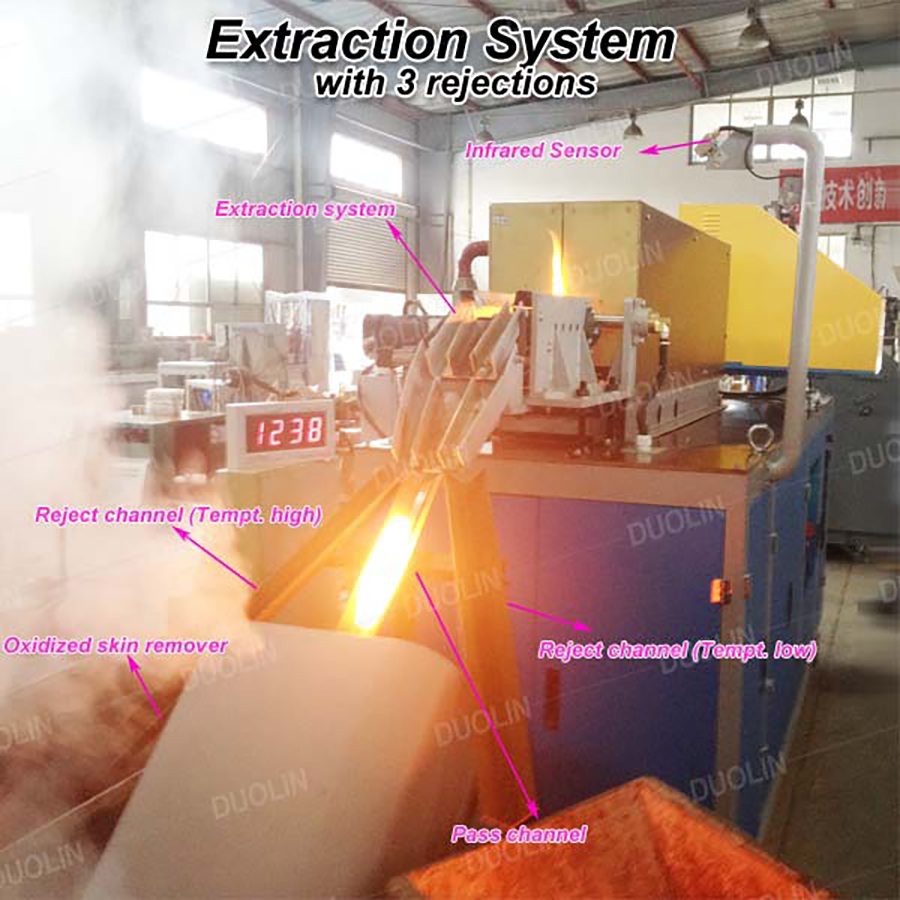

•Support conveyors or chain feeding and temperature sorter system

•Design coil to match with duolin induction converter ensure max output power

•Layout of the complete induction forging system

What’s information we need to know before offer induction heating machine for forging

1:The heat bar material,carbon steel or stainless steel

2: Heating billet diameter and heating length

3: Heating production per hour for each dimension

4: Need total heating or just partial heating

5: Feeding manual or automatic

6: Need infrared thermometer or not

7: Need water cooling system or notWe will make just about every hard work to be excellent and ideal, and accelerate our methods for standing during the rank of intercontinental top-grade and high-tech enterprises for Top Grade China DSP-160kw IGBT Digital Medium Frequency Induction Heating Equipment for Shrink Fit, Striving hard to attain continual accomplishment according to good quality, trustworthiness, integrity, and complete understanding of sector dynamics.

Top Grade China Induction Heating Equipment, Induction Heating Machine, Our team knows well the market demands in different countries, and is capable of supplying suitable quality goods at the best prices to different markets. Our company has already set up a expert, creative and responsible team to develop clients with the multi-win principle.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for China Wholesale Induction System Pricelist - Top Grade China DSP-160kw IGBT Digital Medium Frequency Induction Heating Equipment for Shrink Fit – Duolin , The product will supply to all over the world, such as: Mongolia, Johannesburg, Barcelona, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.