Closed type

Closed type

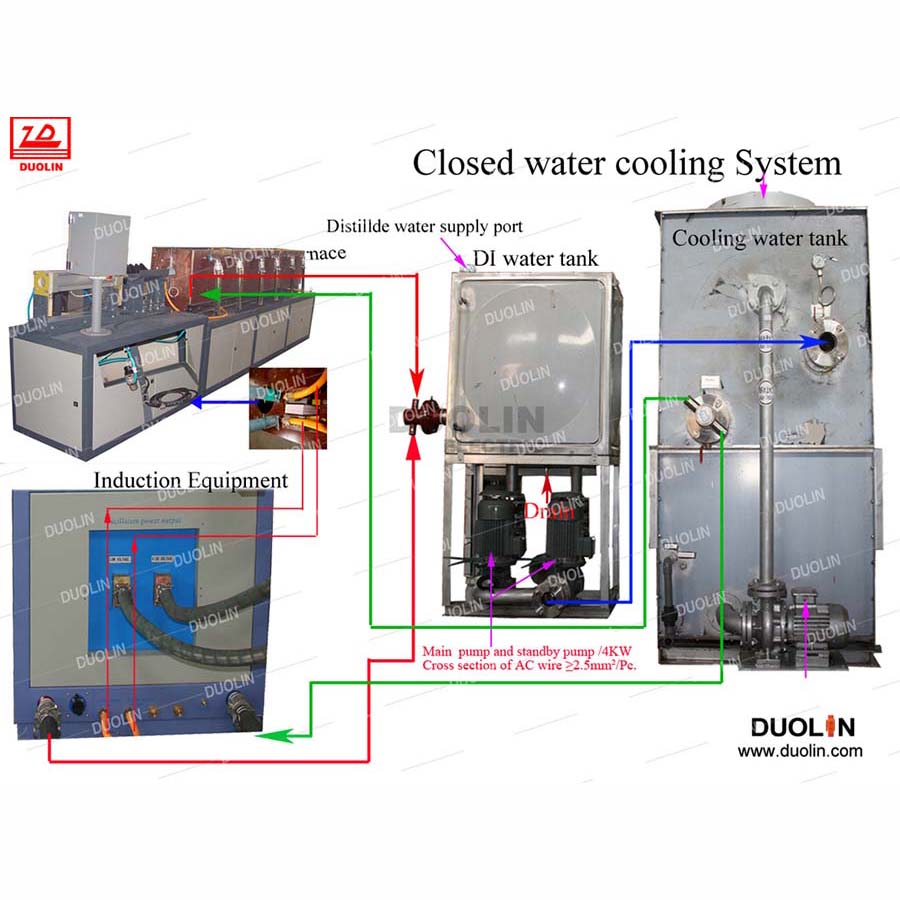

Cooling water shall be free from impurities. DOT NOT use well water or river water .To prevent the scale formation, ensure good cooling result, and greatly reduce the failure rate,Soften Water or Distilled Water are strongly recommended as cooling water for induction equipment.

Water or air cooling is very important for induction heating device,

improves reliability of induction heating equipment, ensure the induction machine working long time and stable. it is easy to install without building water pool and purchasing cooling tower.

Feature

1. The closed tower has a compact structure, a small footprint, easy to move. There is no need to build a pool, which can save a lot of valuable land resources.

2. The pipes of the closed tower are closed, which can ensure that the cooling water is clean under the condition of circulation, so that the cooled equipment can be effectively protected and its service life can be prolonged.

3. Two modes of air cooling and water cooling are adopted, so that the cooling effect is excellent. Equipped with a dehydrator inside, which can effectively reduce the bleaching rate.

4. It can be placed indoors or outdoors. The special cooler design increases the antifreeze performance, scale and corrosion resistance.

5. It has a wide range of uses. It can directly cool quenching liquid, oils, alcohols and other non-corrosive media that have no corrosive effect on the heat exchanger, with no loss of media and stable composition.

6. Using automatic intelligent control, the cooling mode can be automatically changed according to the requirements of the working conditions, and the operation is simple and reliable.

7. Stainless steel water pool, stainless pumps ensure long service time.

8. Water temperature and water pressure detect, automatic liquid alarm protecting the machine from water leakage

9. Use good quality components,such as Schneider,Omron

Closed-cycle cooling medium and no impurity, ensure the purity of the medium;

The use of DI water ensures non-scaling and non-clog in water pipe.

Small space required, easy to move

Low energy loss, operation is simple and reliable.

Cooling water tank and DI water tank use stainless steel to avoid rusting

Specification (For 600KW)

|

Model |

CL-60 |

|

Cooling Capacity |

300000 kcal/h |

|

Cooling water flow |

60 m3/h |

|

Power of Fan |

1.5kw x 2 |

|

Power Input |

380V/50Hz |

|

Wind capacity of fan |

22000 m3/h X 2 |

|

Power of spray pump |

3kw |

|

Water flow of spray pump |

50 m3/h |

|

Lift if spray pump |

13m |

|

Power of main pump |

11kw (two pumps) one main pump and one spare pump |

|

Water flow of main pump |

50 m3/h |

|

Lift of main pump |

48m |

|

Water inlet & outlet |

DN:80 |

|

Working pressure |

0.1~0.45Mpa |

|

Dimension of cooling tank |

2850×1300×2650 |