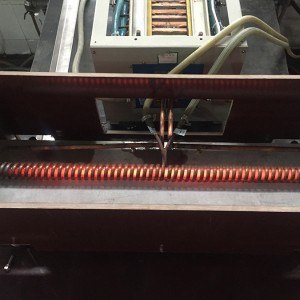

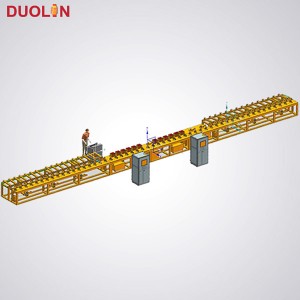

Induction Annealing machine

Products Description

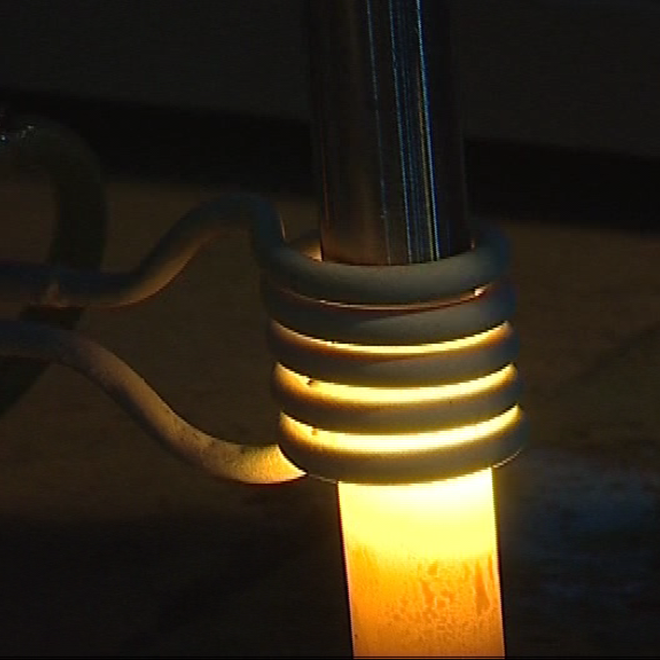

Induction annealing is a kind of heat treatment by induction heater, heat stainless steel or copper to a specified temperature and then cooling at a rate that will produce a refined microstructure. Using Induction heating, metal can be rapidly heated to temperature at controlled an repeated cycles without contacting the metal target, material are usually cooled in open air. The results to change the material’s hardness and strength or other physical properties.

The benefit of annealing with induction heating

1. High production rates

2. Less heating area

3. Save cost due to increased production and reduced labor costs

4. Exactly control heating time and temperature

5.Extend the use life of heating parts

6:Continuous heating no flame or gas,better work environment

Duolin provide induction annealer for wire annealing, pot annealing, tube annealing copper bar induction annealing, by our induction annealing machine with a wide range of output power and frequency.

What we need to know before offer annealing induction solution?

1:The annealing parts dimension,better send us drawing

2: The part material,stainless steel or copper

3:The annealing production