Leading Manufacturer for China Camshaft Hardening High Frequency Induction Heating Machine

We constantly believe that one’s character decides products’ high quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Leading Manufacturer for China Camshaft Hardening High Frequency Induction Heating Machine, We are anticipating to cooperate with you around the basis of mutual added benefits and common development. We are going to never disappoint you.

We constantly believe that one’s character decides products’ high quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Auto Parts Quenching, China Camshaft Hardening Induction Heating Machine, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our merchandise, you can also submit your purchase information online, and we’ll contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

Products Description

| Certification | CE ISO9001 2105 |

| Brand | Duolin |

| Warranty | 1 Year |

| Production capacity | 10 set one month |

| HS Code | 8514400090 |

1:100-160 KW Induction Heating Equipment adopts the IGBT inverter circuit in series connection, which has high heating efficiency

2. High power, fast heating speed, high efficiency and easy operation.

3. The comprehensive full load design is available for 24-hour continuous operation.

4: 160KW IGBT Solid state induction converter, the cabinet is well sealed, no failure and IGBT never burst.

5: Application: Hot forging, Shrink fitting, smelting, surface quench, welding, annealing

6:High conversion efficiency more than 97.5%:IGBT(Insulated Gate Bipolar Transistor)inversion technology

7:Energy saving up to 15%-30% compared with SCR technology induction machine:LC series resonance circuit and voltage feedback design, low energy comsumption

8:Cooper &stainless steel fasteners and radiator,better cooling and anti-electrolysis

Application

1.Preheating (billet hot forging, shrink fitting)

Billet Hot forging aims to heat the work pieces to certain temperature (different materials require different temperatures) into other shapes through forging press with the help of hot stamp or press machine, it can be full or end or head heating of bar,usually use for fastener bolts and nut and other metal related manufacture industry

2.Shrink fitting:Shrink fitting is a heating process to heat metal material creates an interference fit. The increase in hole size allows the insertion or removal of a mating components after heating and cooling.Thank to fast heating speed of induction,temperature can be controlled exactly,prevents distortion and needed metallurgical changes,the thermal expansion creates a joint,gear to shaft,flanges to hubs and bearing insertion are common for shrink fit.

3. Heat Treatment (surface scanner )

Heat treatment for various hardware or tools, such as plier, wrench, hammer, ax, screwing tools and shear (orchard shear).

Hardening for auto part and motorcycle fittings, such as crankshaft, connecting rod, piston pin, chain wheel, pump fitting ,valve, axle shaft, small shaft or steel bar and kinds of gear

Quench for machine tools, such as lathe deck or guide rail.

Induction hardening for hardware molds, such as small-size mold, mold accessory and inner hole of mold

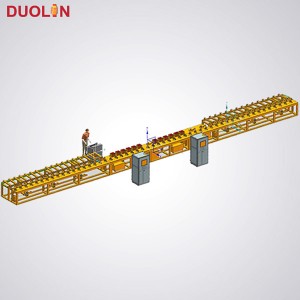

Long bar or thread bar induction hardening and tempering, fully automatic production line

4. Brazing

Induction heating of brazing for kinds of hardware cutting tools, such as diamond tool, saw blade, drilling tool, hard alloy steel cutter, milling cutter, reamer, planning tool and solid center bit and rotor induction brazing

The brazing media are different when materials are not same,Silver is the most common,the soldering part are hardware toilet and kitchen products, refrigerating copper fitting, lamp decoration fitting, precision mold fitting, hardware handle, eggbeater, alloy steel and steel, steel and copper as well as copper and copper.

It is also applicable to plain braze welding of other metals.We constantly believe that one’s character decides products’ high quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Leading Manufacturer for China Camshaft Hardening High Frequency Induction Heating Machine, We are anticipating to cooperate with you around the basis of mutual added benefits and common development. We are going to never disappoint you.

Leading Manufacturer for China Camshaft Hardening Induction Heating Machine, Auto Parts Quenching, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our merchandise, you can also submit your purchase information online, and we’ll contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.