OEM Customized China Magnetic Induction Metal Forging Machine (JLZ-35)

we could supply good quality goods, aggressive cost and very best purchaser assistance. Our destination is “You come here with difficulty and we supply you with a smile to take away” for OEM Customized China Magnetic Induction Metal Forging Machine (JLZ-35), Sincerely hope to develop long-term company associations along with you and we are going to do our greatest provider for you.

we could supply good quality goods, aggressive cost and very best purchaser assistance. Our destination is “You come here with difficulty and we supply you with a smile to take away” for China Metal Forging Furnace, Forging Furnace, our qualify solutions have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can supply a safe, environmental items and super service to our clients from all of the world and establish strategic partnership with them by our qualified standards and unremitting efforts.

Products Description

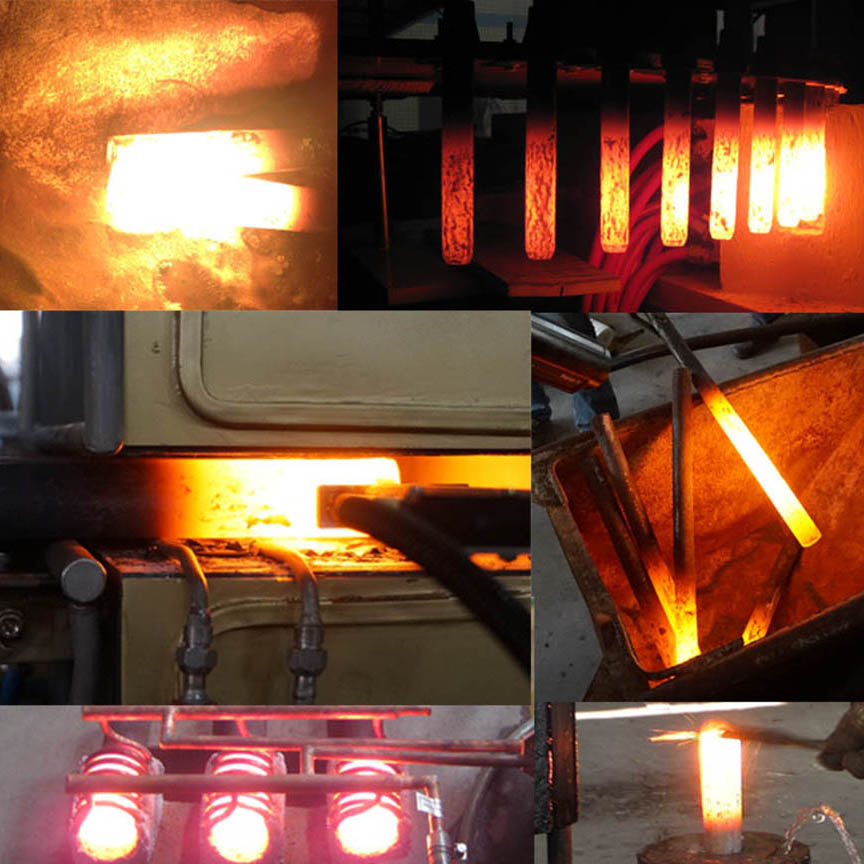

Induction forging refers to use an induction heater to pre-heat metals before forging and forming. Typically metals are heated to between 1,100 and 1,200 °C to increase their malleability and aid flow in the forging die.

Induction produces less oxidation, easy to control heating temperature and time, heat rapidly, ensure good quality of forging work piece, protect tool of forging machine.

Induction billet heating line for total heating

Induction heating equipment with slot inductor for partial heating

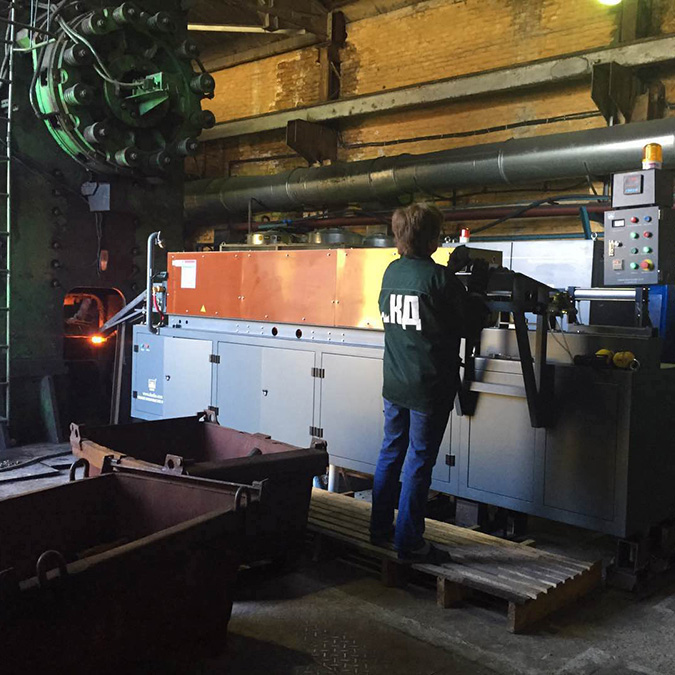

Integrated induction heat line: induction power supply built in with inductor, less space requirement, PLC control.

Induction heating technology is increasingly being used for industrial forging applications because it offers an unbeatable combination of speed, consistency, control and efficiency.

DUOLIN offers induction billet heater used for heating a wide range of bar and billet diameters.induction power supply is the latest generation; help you benefit from modern forging industry.

• No combustible gases

• Heating rapidly reduce oxide skin on billet

• Improve the working environment

• Uniform heating temperature increases die life

• Continuously working, 24 hours non-stop

• Be Started up 100% at any load

• Less interference to others equipment in workshop (Proved by CE)

• IGBT inversion technology & LC series circuit design achieve energy saving up to 15%-30% compared with SCR technology

• Easy to operate and maintain

• Offer PLC to complete fully automatic production line and high heating output

•Support conveyors or chain feeding and temperature sorter system

•Design coil to match with duolin induction converter ensure max output power

•Layout of the complete induction forging system

What’s information we need to know before offer induction heating machine for forging

1:The heat bar material,carbon steel or stainless steel

2: Heating billet diameter and heating length

3: Heating production per hour for each dimension

4: Need total heating or just partial heating

5: Feeding manual or automatic

6: Need infrared thermometer or not

7: Need water cooling system or notwe could supply good quality goods, aggressive cost and very best purchaser assistance. Our destination is “You come here with difficulty and we supply you with a smile to take away” for OEM Customized China Magnetic Induction Metal Forging Machine (JLZ-35), Sincerely hope to develop long-term company associations along with you and we are going to do our greatest provider for you.

OEM Customized China Metal Forging Furnace, Forging Furnace, our qualify solutions have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can supply a safe, environmental items and super service to our clients from all of the world and establish strategic partnership with them by our qualified standards and unremitting efforts.